The mass manufacturing of a product is an important milestone for many businesses. It’s a sign that there is a strong demand for a product, and the company needs to scale up to meet it.

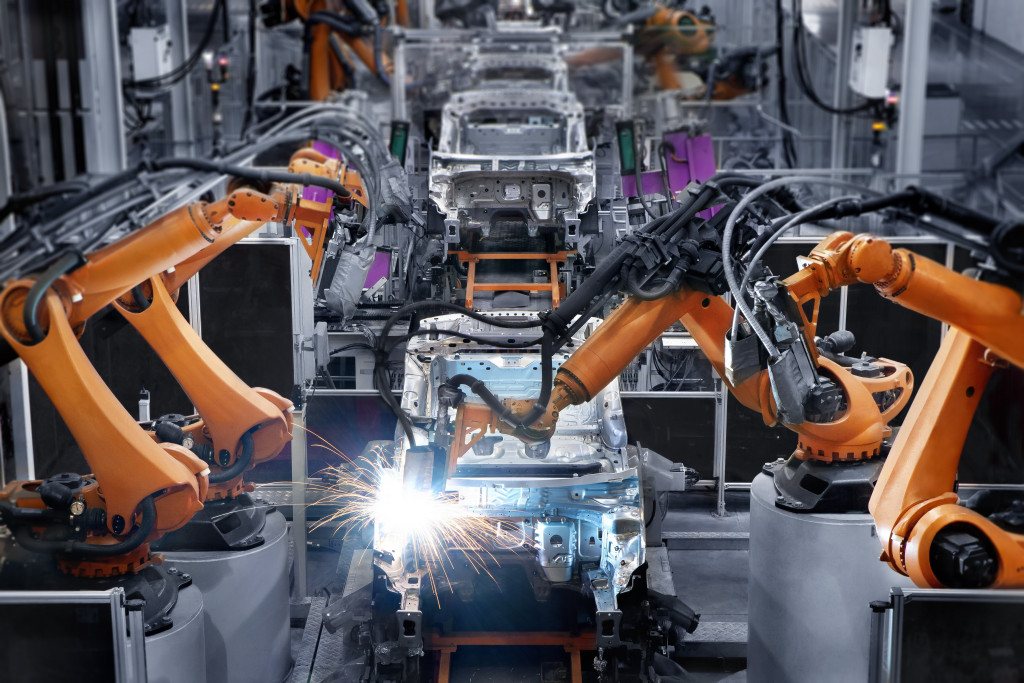

It can be quite scary to spend the money to go from a small-scale production with a few employees to a large-scale manufacturing operation. It requires equipment such as a large part injector and large-part injector molder, heavy machinery, and others. There’s also a lot of effort and risks involved.

However, mass production of a product still has its perks. Here are some pros and cons to help you decide whether the benefits outweigh the disadvantages.

Efficient Use of Resources

The more efficient use of resources. Manufacturing in high volumes allows companies to keep costs down because they’re producing many goods at once. This also means they can afford more labor, equipment, and technology.

For example, they can purchase more efficient machines to cut production time and costs. Additionally, the large-part injector molder reduces labor costs because certain parts are now molded with one machine. This is why many companies choose to invest in high-volume production before outsourcing their manufacturing needs to a third-party manufacturer or maker of custom products.

More Efficient Distribution Chain

How do you ship your product from the factory floor? A large-scale manufacturer has enough capacity to invest in proper transportation equipment, such as large trucks and containers. With a smaller manufacturing operation, there might not be enough production volume to justify these costs, which could potentially increase manufacturing costs.

It also limits possible errors by eliminating human error during filing, polishing, and other tasks that need to be done by hand. This makes it easier to fulfill a high number of customer orders because employees don’t waste time doing manual labor between machine tasks.

Other Benefits

Manufacturing large scale could provide several benefits aside from cost reduction and efficient distribution chains. For example, you might be able to enjoy better service from your manufacturer if they have highly trained specialists who can handle complex projects with ease. Large manufacturers usually work with clients who constantly require their services, which gives them more chances to hone their skills and deliver quality products.

Increased Risks of Product Defects

There are several disadvantages to mass-producing a product. One of the main ones is the increased risk of product defects. This is because there is a detachment between each worker’s tasks. With everyone doing their own thing, it’s easier for something to go wrong. This is why it’s important to use quality manufacturing equipment and skilled workers.

Loss of Quality

Additionally, with so much emphasis on volume, companies can often lose sight of their original goals and values. It becomes all about churning out products as fast as possible, without regard for quality or customer satisfaction.

Another risk of producing on a large scale is that manufacturers might cut corners in order to meet the demand for goods or cut costs, which can negatively impact your product quality.

When quality is lost, the company might lose future business, especially if it sacrifices quality in an effort to make short-term gains.

Other Disadvantages

Unfortunately, many businesses overestimate the demand that the public has for a specific product. There is a chance that they won’t sell as much as they initially thought. If this happens, the company might need to slow down production or reduce its workforce.

If they flood the market with too much merchandise, they might find the demand decrease. The product loses its rarity which makes it less of a must-have and, because it’s lower cost, fewer people will want it.

Another downside of mass-production is that it can become too expensive or yield losses for some businesses. It might also be too costly for smaller companies to invest in the tools necessary for large-scale production. They may not have enough volume to justify these tools, which could potentially increase manufacturing costs.

Businesses should weigh the pros and cons before making a decision. Manufacturing large-scale could be a chance for a business to boost sales and build an empire. It can also lead to the downfall of the business if the steps taken end up being too risky for the company.

The business should consider outsourcing to a third-party manufacturer if their product demand isn’t high enough for large-scale manufacturing, and they don’t want to cut costs by reducing their workforce or slowing down production. With that said, it really just depends on what the company is trying to accomplish and how much risk they’re willing to take before investing in large-scale manufacturing.